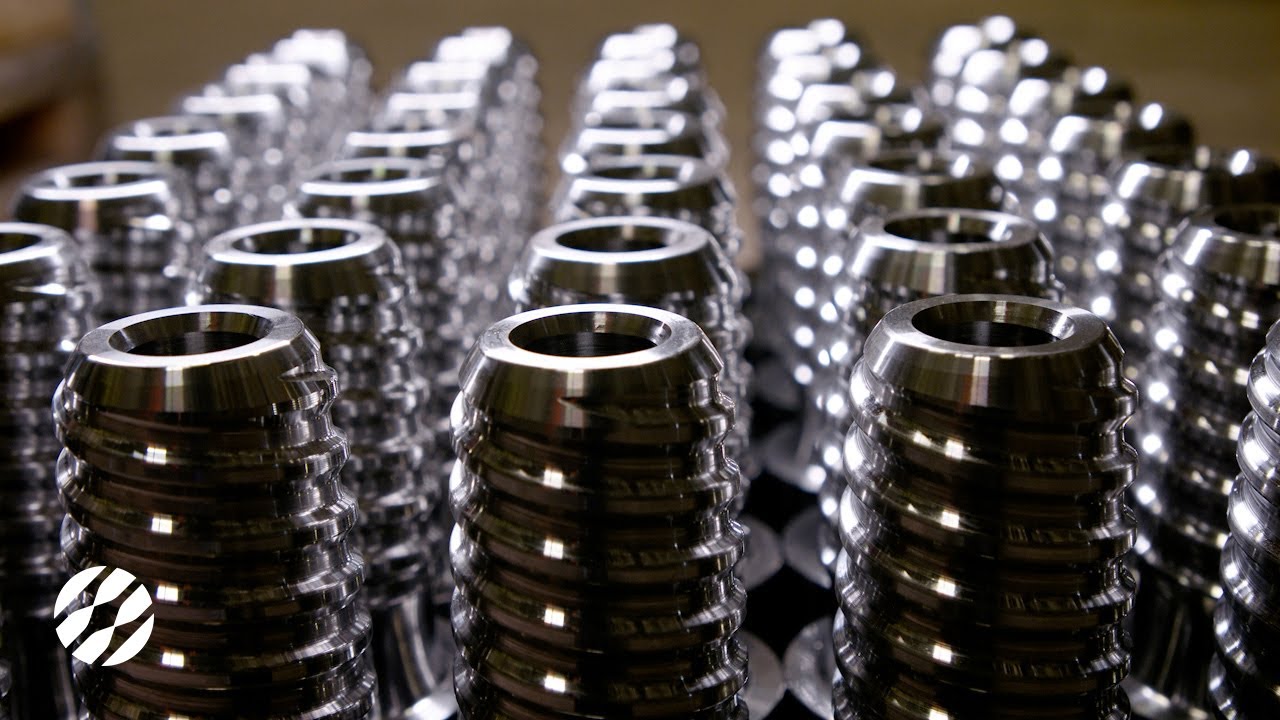

Packed with power CT55 and CT67

Curved thread innovation

The new top hammer curved thread systems, CT55 and CT67, push the limits for productivity, durability and sustainability. With a higher penetration rate, improved hole straightness, better flushing, fewer breakages, and hassle-free coupling and uncoupling, you want to experience the power of the latest innovation from Sandvik for surface bench drilling and underground long hole drilling.

The most advanced tool system ever made

Features, benefits and values

Learn all you need to know about our latest innovation

Curved thread deep dive #1

Stronger design means longer tool life and higher productivity for our CT family.

Curved thread deep dive #2

Drill faster while still achieving longer tool life and great hole quality.

Curved thread deep dive #5

Increased tool life due to high wear resistance.

Curved thread deep dive #6

Stop fishing and spend your time drilling instead. Choose trouble free rock tools.

Curved thread deep dive #7

Stiff rods generate straighter holes even with high feed pressure. In combination with the shoulder connection of the CT tool system this ensures rigidity and hole accuracy like never before.

Curved thread deep dive #8

Surface drilling - one system to conquer the hole. Our new CT tool systems are developed for perfect drilling dynamics, matching our Sandvik rock drills.

Curved thread deep dive #9

The new rock tools will not solve all problems on the automation journey, but they will allow mines to focus on all the other challenges.

Curved thread deep dive #10

Discover how to get higher drill speed and consume less fuel per drill meter using CT system.

Curved thread deep dive #11

The CT systems are ideal for mines looking to increase productivity and reduce costs.

Stronger than ever for surface drilling

Our new CT tool systems are developed for perfect drilling dynamics, matching our Sandvik rock drills and Panthera DPi and Ranger DXi drill rigs. Using the full capacity of the drill rig generates higher drill speed and productivity, maximizing the output for every engine hour. The curved threads enable trouble-free drilling through seamless coupling and uncoupling properties. Furthermore, CT55 and CT67 ensure better hole quality and straightness, setting new standards for precision in surface drilling operations.

The CT55 and CT67 bench drilling tool systems give you a lower cost per drilled meter and a significant reduction in total drilling expenses. The enhanced service life and decreased tool breakages lead to increased operational efficiency and cost savings. Additionally, CT55 and CT67 will radically reduce your fuel consumption and lower the carbon footprint.

Underground drilling without interruptions

All the weaknesses identified in the industry standard ST58 and ST68 tube drilling systems have been transformed into strengths with the new CT55 and CT67 accordingly. Regardless of whether your drill tubes today are discarded due to breakages or worn-out threads - the CT system is much stronger in every aspect. Upgrade your drilling experience with our most powerful thread innovation to date.

Uncoupling problems and sudden transversal breakages cost lots of time and are entirely unpredictable. The CT55 and CT67 top hammer tool systems are built to last and deliver without interruptions. The exceptional service life of the CT system ensures lower cost per meter and less manual handling of heavy products. The curved thread design is innovated for effortless coupling and uncoupling, essential for smooth drilling and seamless automation.

Breakages and fishing of lost tools underground is now a rarity

Robert Grandin

Product manager for Top hammer underground tools,

Sandvik Mining and Rock Solutions

Finally the installed drill power can be fully utilized.

Fredrik Björk

Product manager for Top hammer surface tools,

Sandvik Mining and Rock Solutions

PowerCarbide® - powerful feature

PowerCarbide® is our most advanced materials technology and can optimize any drilling application. In the new top hammer curved thread systems, CT55 and CT67, we use two types of PowerCarbide® – GC81 and SH70.

SH70 has "self-hardening" grades that can become more wear-resistant and tougher as drilling progresses.

The GC81 carbide has a hardness gradient grade with high wear-resistant on the outside, while the center provides the needed toughness.

Rock Tools sustainability report

At Sandvik Rock Tools we are determined to take action when it comes to sustainability. We are on our most important journey to date - to make the mining industry as sustainable as possible and secure the necessary minerals we needed to make the shift towards a sustainable future.

This report, that we call the “Our Way Report”, is created to give our customers, employees and other important stakeholders an annual overview of where we stand in terms of the progress of our sustainability efforts.