A (r)evolution in top hammer drilling

New Sandvik Alpha® 340 asymmetric drilling tools are the latest innovation in top hammer drilling for mine development and tunneling. Inspired by the force of evolution and powered for a successful drilling operation.

The power of innovation

Innovating for tomorrow is in our DNA. The power and durability of the evolution are sources of inspiration for the asymmetric thread in the new Sandvik Alpha® asymmetric drilling tools. We call it a (r)evolution, as it shapes the future of mine development and tunneling.

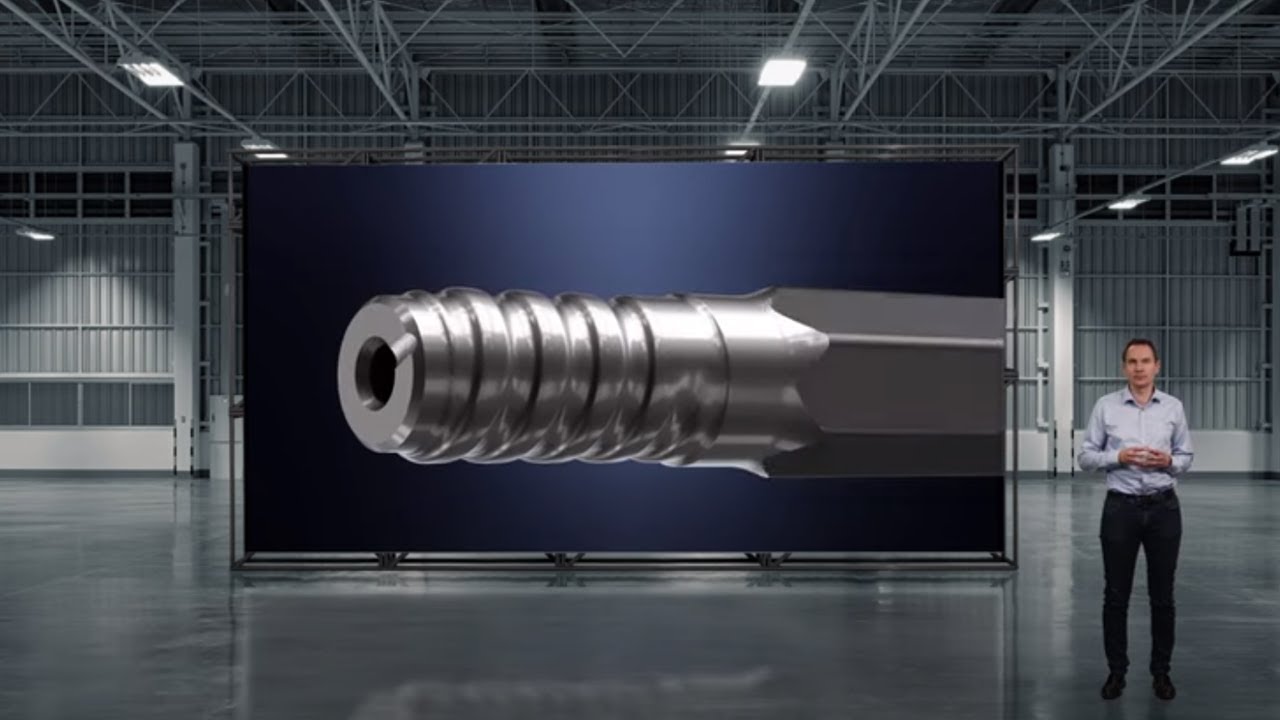

Sandvik Alpha® 340 asymmetric drilling tools thread

Downloads

Meet the team behind the innovation

Innovation is in the core of our business, and just like nature, we continue to evolve. Meet the team and get to know the story behind our latest innovation for mine development and tunneling - Sandvik Alpha® asymmetric drilling tools.

Listen to our experts

Listen to our experts in this digital event and discover more on how the new asymmetric thread design in Sandvik Alpha® 340 asymmetric drilling tools can (r)evolutionize your profit.

Our customers liked the old Sandvik Alpha® 330 drilling tools and didn't see any reason to change them. That was until they tried the new Sandvik Alpha® 340 asymmetric drilling tools.… The results coming back from our users are astonishing.

Robert Grandin

Product Manager, Rock Tools Top Hammer Underground

PowerCarbide®

PowerCarbide® is our most advanced materials technology and can optimize any drilling application. In Sandvik Alpha™ Asymmetric drilling tools, we use three types of PowerCarbide® – GC81, SH70, and XT49.

SH70 has "self-hardening" grades that can become more wear resistant and tougher as drilling progresses.

GC81 carbide has a hardness gradient grade with high wear resistant on the outside, while the center provides the needed toughness.

The XT49 grade is more resilient against breakages, enabling more button protrusion and a sharper geometry for faster drilling.

Design for you and the environment

Underground drilling involves a lot of challenges. New Sandvik Alpha® 340 asymmetric drilling tools are a wise choice for the environment and the workplace safety. The prolonged rod life means fewer rod changes and less heavy lifting for the driller. It is also a more sustainable choice for the environment.

Sandvik Alpha® 340 asymmetric drilling tools are included in our Rock Tools Recycling Program of used cemented carbide tools. The metal will be converted back into basic raw materials and reused.

Learn more about the calming effects of Rock Tools Recycling here.

Sandvik Alpha® asymmetric drilling tools Q&A

-

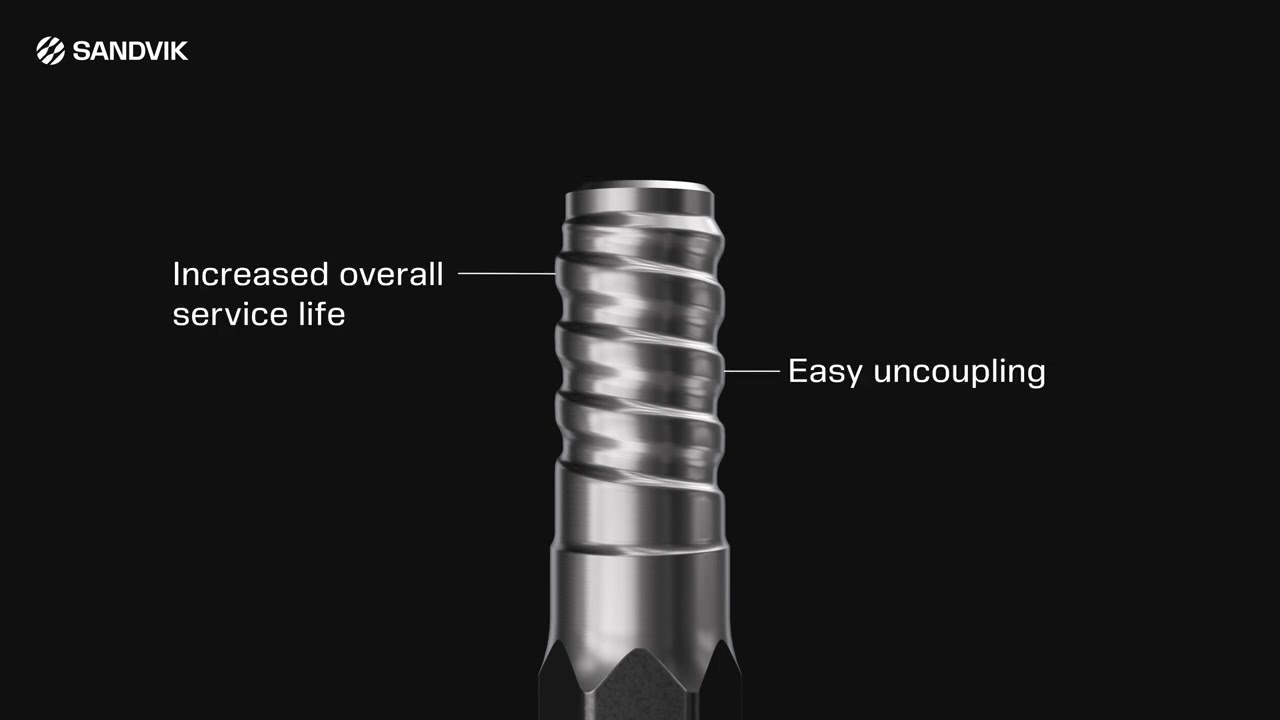

What do you mean by an asymmetric thread?

It means that the flank angles of the thread profile are different. The purpose is to reduce the stress level of the tightening flank, where many breakages begin.

-

Will Sandvik Alpha® 330 still be available?

No. All customers will be transitioned to the new Sandvik Alpha® 340 the following year. The current users of Sandvik Alpha® 330 will be contacted about the conversion by the Sandvik Rock Tools sales teams. This process is synchronized with factories and has already started.

-

Is Sandvik Alpha® 340 compatible with Sandvik Alpha® 330?

No, it is not. Sandvik Alpha® 340 has a different thread profile, diameter, and pitch.

-

What is the difference between Sandvik Alpha® 360 and Sandvik Alpha® 340?

They are built on the same technical platform but are scaled toward different diameters. Sandvik Alpha® 360 is optimized for 48-51 mm hole size, and Sandvik Alpha® 340 can drill down to 43 mm holes. The bigger thread diameter on Sandvik Alpha® 360 will make the rods last much longer for the larger hole sizes.

-

What do you mean by PowerCarbide® grade?

PowerCarbide® is a family of cemented carbide grades, which have an elevated technology compared with industry standards. They are unique to Sandvik Rock Tools and increase the value of your drilling operations.

-

What are the advantages of PowerCarbide®?

The technology platforms which make up PowerCarbide® can be scaled towards different customer values. In many bits, the difference will be seen as higher wear resistance, meaning longer grinding intervals and total service life. But in others, such as Speedy Bit and Autobit, the PowerCarbide® technology is an enabler for more protrusion and a pointier button shape – which increase drill speed and makes them drill well even when the buttons are worn.

-

Do I need to change also the shank adapter and coupling?

No, the Sandvik Alpha® thread concept only impacts the bit end of the drifter rod. The shank end is still the industry standard thread T38.

-

Can I use Sandvik Alpha® Asymmetric drilling tools for long-hole drilling?

No, Sandvik Alpha® threads are designed only as a bit thread for one-rod drilling in tunneling and mine development. There are unique products, such as a cross-over coupling in the assortment, which can be used for special applications in limited amounts. Sandvik Alpha® Asymmetric drilling tools are not recommended for extensive drilling.

-

When do you recommend hexagonal or round drifter rods?

Round rods give the best hole quality and generate the least wear on centralizer

bushings. The hexagonal rods are better for getting the cuttings out of the hole and tend to jam much less. In general, round rods work best when the rock is competent and the hole size has a minimum of 45 mm. Because of the better hole accuracy, round rods are more useful the longer your holes are. For fissured ground, such as bolting applications, hexagonal rods are preferred.