Upgrades & Engineered solutions

Compressor Conversion kit

Hole flushing is necessary to remove cuttings from the drilled hole. To get the best performance from your equipment, hole flushing must be optimized.

-

Description

Hole flushing is necessary to remove cuttings from the drilled hole. To get the best performance from your equipment, hole flushing must be optimized.

Pressure and flow rate delivered by the compressor must be adapted to several factors such as the drilling method (rotary or DTH), the drilled hole size (diameter and length), the type of rock or even the working altitude. If one or more of these factors change, Sandvik offers customers the compressor conversion solution.

Contact your local Sandvik dealer to determine the best option for your application. The kits includes all parts needed to do the modification.

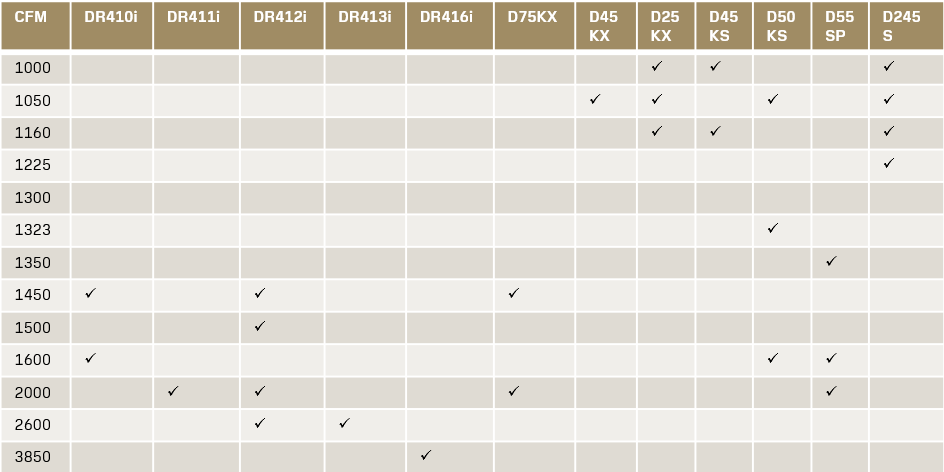

The Compressor Conversion kits are available for all Rotary Drills:

How to order

Request a quote

You can request a quote directly here on our web site. Specify which type of products you're interested in and we'll get back to you as soon as possible.

Find an office

Contact any of our offices around the world to talk to a representative that will help you order the products you want.

My Sandvik Customer Portal

View which upgrades are specifically available to the equipment in your fleet.

You can also purchase thousands of products, keep track of your fleet’s data and manage your business directly online.