CT55 and CT67

CT55 and CT67 for surface

- Hole diameter CT55 (new T51)

- 89.0 - 127.0 mm (3.5 - 5.0 in.)

- Hole diameter CT67 (new GT60)

- 102.0 - 152.0 mm (4.0 - 6.0 in.)

- Flushing house

- 70 mm (DXi), 80 mm (DPi), 90 mm (DPi)

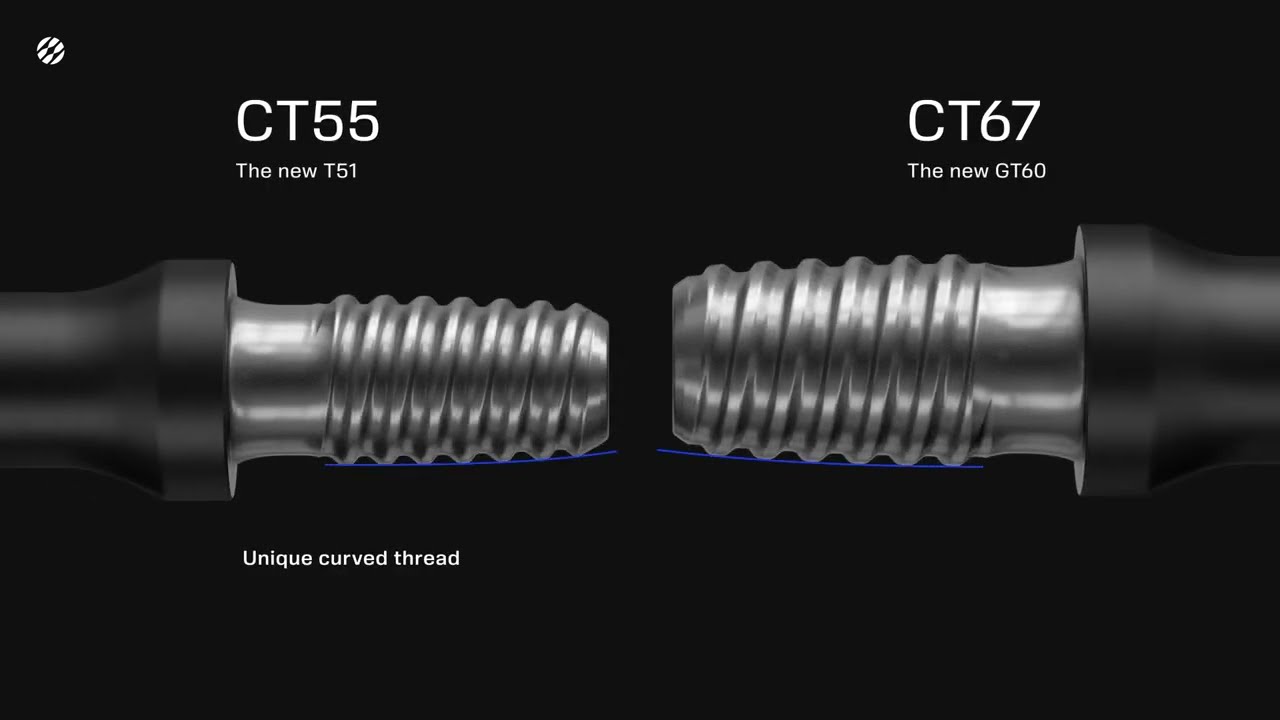

CT55 and CT67 curved thread systems are designed for surface mining and quarrying. These systems accommodate higher drilling power than the standard ones and feature a curved profile that reduces stress levels strategically while optimizing the product for fatigue strength.

Features

-

Patented design

The unique, patented curved thread system provides a bigger X-section where needed and significantly reduces stress levels. This leads to fewer breakages and increased service life.

-

Productivity boost

The curved threads achieve a faster rate of penetration per meter and more meters per engine hour. These factors - along with problem-free drilling, easy coupling/uncoupling and good hole quality/hole straightness - provide increased productivity during drilling operations.

-

Advanced technology

The specially developed shoulder-driven system achieves an efficient energy transfer along with a stiff, strong connection. Easy coupling/uncoupling leads to minimal rattling.

Product specifications

CT55 and CT67 for surface operating manual and spare parts

Operating manuals and spare parts can be found on the My Sandvik customer portal.

- Hole diameter CT55 (new T51)

- 89.0 - 127.0 mm (3.5 - 5.0 in.)

- Hole diameter CT67 (new GT60)

- 102.0 - 152.0 mm (4.0 - 6.0 in.)

- Flushing house

- 70 mm (DXi), 80 mm (DPi), 90 mm (DPi)

Curved thread innovation

Packed with power

Learn how a curved top hammer thread makes all the difference. The CT55 and CT67 bench drilling tool systems give you a lower cost per drilled meter and a significant reduction in total drilling expenses. Check out other features, benefits and values.

Can't find the answer to your questions?

Are you looking for a spare part or component?

Visit My Sandvik customer portal where you can find information such as price and availability for our parts and components.